How are fire resistant cables tested?

Previously we explored the reasons why we need fire resistant cables and what materials are used to create our FP cables. This month, FP cable expert Martin Boorman looks at how Prysmian fire resistant cables are tested.

The Prysmian FP range is specifically designed to maintain circuit integrity and continue to work for a specific time under defined conditions of 30, 60, or 120 minutes. Our FP cables help save lives in a fire and provide greater property protection. However, in order for these cables to do their job, they need to be rigorously tested.

British Standards

The British Standard Institution (BSI) publishes British Standards for a wide range of uses underlined by their principle to ‘make excellence a habit’. Amongst others, BSI create and publish British Standards for the fire testing of cables. The Standards for fire resistance set out to test the integrity provided by a cable during a fire. In particular, circuit continuity at rated voltage.

Each of these Standards is a specification for the actual fire test. They detail the design and dimensions of test rigs and how many cable samples are required, how they are prepared and how the burners should be calibrated.

They list the methods of cable fixing, how circuit continuity is measured, the test voltages, flow rate for water spray and the burner gas and air mixture. These standards are the handbook for fire testing professionals and Prysmian have two full time fire test engineers ensuring the procedures are rigorously applied.

BS EN 50200: Method of test for resistance to fire of unprotected small cables for use in emergency circuits

Originally written as the ‘EN’ or European Norm standard with UK experts provided by BSI, it was adopted by BSI and published as a ‘BS EN’ in 2000. The 2006 revision replaced its predecessor and the BS 8434-1:2003, which has since been withdrawn.

This is a test for small cables (it defines up to and including 20mm diameter) with a flame temperature of 830°C and a mechanical shock. This shock is provided by a steel bar striking the predefined backboard the cable is fixed to at specific intervals for the duration of the test.

The test durations are 15, 30, 60, 90 & 120 minutes with cable integrity given as PH15, PH30, PH60, PH90 or PH120 should they pass.

The 2006 review was revised to incorporate the water spray element of BS 8434-1 into its Annex ‘E’. This means that ‘standard’ fire resisting cables required by BS 5839-1 MUST achieve PH30 AND Annex ‘E’ of BS EN 50200. This requirement was kept in the 2015 revision and is still current.

So, two fire tests are now within the same standard. For emergency lighting systems described by BS 5266-1, ‘standard’ fire resisting cables are required to achieve PH60 classification PLUS the thirty-minute water spray, flame and mechanical shock test BS EN 50200 Annex E. This is still a regular discussion point with Prysmian: ‘standard’ fire resistant cables must pass TWO fire tests ‘Annex E’ PLUS PH30 or PH60 as appropriate.

BS 8434-2:2003+A2:2009: Methods of test for assessment of the fire integrity of electric cables. Test for unprotected small cables for use in emergency circuits. BS EN 50200 with a 930°C flame and with water spray

This test method is used to assess a cable for ‘enhanced’ fire resistance required for applications in fire detection, fire alarm, emergency lighting and Category 2 life safety and fire-fighting control circuits. As the title implies, it is for small cables but at a higher nominal flame temperature, 930°C as opposed to 830°C.

BS 8434-2 is a two-hour (120 minute) test which includes direct flame, mechanical shock and a water spray, all conducted on the same cable sample in the same period. Cables that are required for ‘enhanced’ fire resisting circuits must meet BS EN 50200 PH120 classification and they must also meet BS 8434-2. BS 8434-2 is for the additional performance required by ‘enhanced’ fire resisting cables and is the procedure used by the fire test engineer to confirm its suitability. ‘Enhanced’ fire resistant cables must achieve higher flame temperature for a longer period.’

BS 8491: Method for assessment of fire integrity of large diameter power cables for use as components for smoke and heat control systems and certain other active fire safety systems

This fire test procedure supports the use of fire resistant armoured power cables, larger than 20mm diameter, for life safety and fire-fighting systems required for large and complex buildings. Fire risk assessments of these buildings typically result in the requirement for a wide range of applications including fire-fighting lifts, smoke and heat exhaust ventilation (SHEV) plus fire barriers. All of which require integrity of their power circuits and this fire test is applied to confirm suitability of the cable. BS 8491 incorporates direct attack by flame, direct mechanical attack by steel bar and direct water applied by water JET. All of these are applied to one sample in the same test, and all applied at the minimum bend radius for the cable for two hours; the ultimate fire test.

BS 8491 is also part of the fire test engineer‘s reference. It provides methods to calibrate the rig, prepare cable samples, conduct the test and record the result correctly. It is still in the first edition, published in 2008.

BS 6387: Test method for resistance to fire of cables required to maintain circuit integrity under fire conditions

This British Standard released in 1983, is a fire test procedure only. It was last revised ten years ago. Between 1983 and 2000, it was the only UK fire resistance test for circuit integrity with water, and it had become synonymous with the requirements for emergency systems. Even though it is still current, it is no longer required for any UK emergency building services.

Prysmian FP products and their fire tests

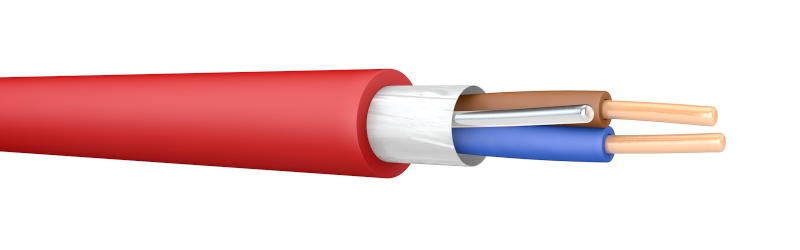

FP200 GOLD

The FP200 GOLD is a ‘standard’ fire resistant cable required to meet an integrity time of 30 minutes when tested to BS EN 50200 (PH 30); and a survival time of 30 minutes, when tested to BS EN 50200 Annex E—which is exposure to fire, impact, and water spray.

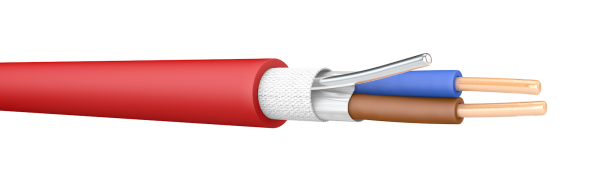

FP PLUS

FP PLUS is an ‘enhanced’ fire resistant cable required to meet an integrity time of 120 minutes when tested to BS EN 50200 (PH 120); and a survival time of 120 minutes when tested to BS 8434-2 – which is a longer, hotter test than Annex E.

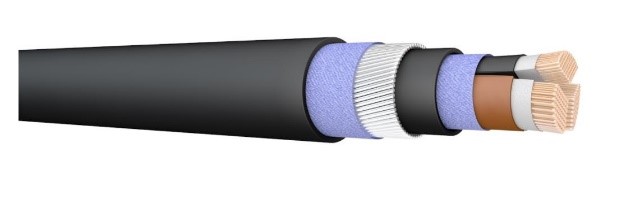

FP600s

FP600s is an armoured fire resistant cable required to meet the BS 7846 Category F120 Construction Standard and the BS 8491 120 Minutes Fire Resistant Test which is Flame, Shock & Water JET – for 120 Minutes.

These Prysmian FP cables also comply with BS EN 61034-2 Smoke Emission test and the BS EN 60754-1 Corrosive and Acid gas tests required by their relevant BS construction specifications.

It is important to rigorously test fire resistant cables to ensure they perform effectively for their whole life and not just in the event of a fire. For example, emergency systems must be checked regularly so the cables must also be able to perform for the checks to ensure the rest of the system functions as it should.

As well as developing and testing cables in our labs, all Prysmian FP cables receive independent assessment and certification from BASEC and LPCB. This not only illustrates our diligence and professional integrity, but also provides building owners, designers and installers with the peace of mind they can expect from Prysmian.

Learn more about the products in our FP cable range in part four of our FP blog series…